Our Products

- Low temperature, High dust load applications

- Filtration of high temperature up to 400°C or more

- Fuel gas from coal-fired boilers in power plants

- Dust capture from solid waste incineration

- Filtration of toxic Gas with high content of polluting metallic elements.

- Filtration of corrosive and other chemically active dust.

- Capture of high value dust such as gold, silver & titanium.

- Investives to improve plant layout and to manage

filtration problems. - Undertake dust collector rehabilitation & maintenance engagements.

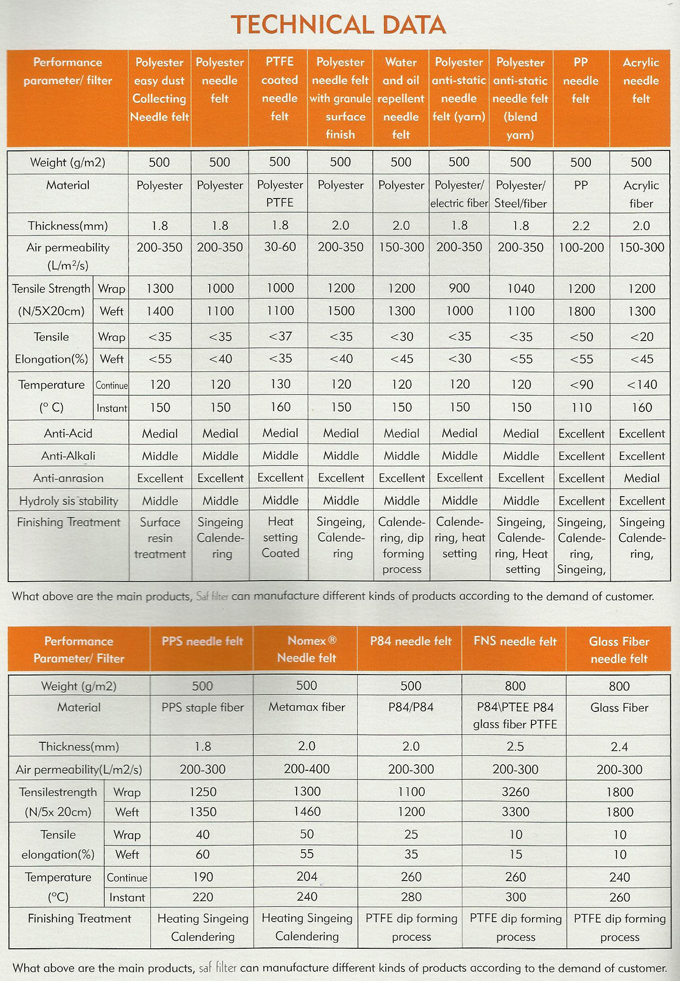

Filter Bags

wif filter bags, made from high quality felts and woven fabrics are sewed to meet specific requirements and exacting dimensional standards of several key industries. These sophisticated products are manufactured using computerized management of technical drawings, models and specifications. The continuous manufacturing cycle maintains quality of fibres besides minimizing defects and confectioning mistakes.

Following Types of Filter Bags are made for complete customer satisfaction.

Air Slide Pneumatic Conveyor Systems consist of Air feed unit like blower, metallic bellow or compressor which are the sources of air stream supply; product feed pneumatic conveyor comprising two pressurized chambers or channels, positioned one upon another at their open trough ends with the Air Slide Fabric separating them. The pressurized air is fed into the bottom chamber and permeates through the fabric entering the top chamber where it picks up the product being feed into it at the upper gradient end transports it to the collection point at the lower gradient end.

There is an air separation arrangement at collection point or filter unit, which separates the solid powder product stream from the air stream. This may be a cyclone separator, bag house filter or precipitator and material product is collected in bin, silo, or hopper either for storage or mixing or blending or if in a finished product stage to the packing plant.I am text block. Click edit button to change this text. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

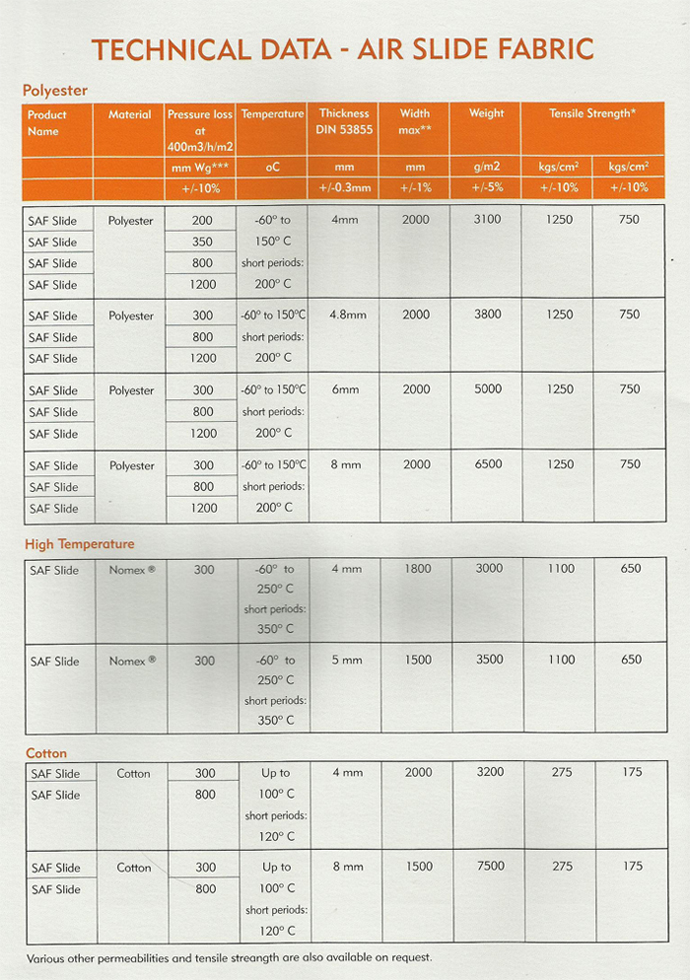

Air Slide Fabric

We manufacture and export special fabrics for Air Slide Belts used in pneumatic conveyor lines. Furthermore, our company has also introduced aeration and handling of powdered materials in silos, hoppers and stacks such as in cement works, lime factories, chemical plants and mining. These Industrial Air Slide Fabrics are preferred by many distinct industries to cater their wide requirements. The multi-ply structure of the fabrics with varied weight, thickness and permeability enables uniformity in the flow effect on the slide surface, greater mechanical resistance to abrasion and tensile strength and a vast porosity range. Air Slide Belt Fabric produced by us is best suitable customers’ diversified needs and can be obtained at a very cost effective price that suits to their budget.

Description

- Air Slide Fabrics produced from 100% Polyester (spun/filament), 100% cotton, 100% Nomex® in widths of 200mm up to 2000mm and thickness in 3.0, 4.0/4.5, 4.8 /5.0, 6.0/6.5/8.0/10/12mm.

- Available in roll lengths and cut pieces to actual installation size & shape.

- Materials inspected & tested with Test & Guarantee Certificates provided.

- Air Slide Fabrics for all Pneumatic gravity Conveyor System i.e. Air Slide, Fluidor, Fluxo-Channel Fluid Slide, Aeration – Box, Airlift or Aerpole pumps in Sillo, Bin & Hopper.

- For bulk material conveying fine crushed and ground powdered chemical mineral substances used to manufacture cement as well as any other similar powdered products.

- Our “Air Slide Fabrics” have good abrasion resistance offered in 100% Synthetic qualities of polyester to withstand organic and inorganic chemicals, acids, alkalis and oxidizing agents contained in raw mix, clinker and cement.

Filter Bag Cages and Venturi

We offer a complete line of replacement and custom designed dust collector filter cages to fit most manufacturer filter bag housings.

We manufacture cages made out of GI/MS/SS in various wire diameter from automatic cage welding machines.

Our cages are used in most bag houses as they are designed to serve as critical bag house components for optimum bag performance and durability. These are traditionally constructed of one of Low carbon steel (bright basic wire), Galvanized low carbon steel, Type 304 stainless steel and Type 316 stainless steel. These are available in custom or standard sizes-for new and old collectors, In-house tooling for most OEM cages. These are ideal for Snap Band, Clamp on, Top load and bottom load or pulse jet. Coatings: low & high temperature epoxy, Zinc, Teflon and all others Cage Constructions: All gauges any number of vertical wires and horizontal rings, round, oval cage or envelope cage, double rolled flange, rolled band, wire top. crimped cup welded cup formed cup curved cup and all others.

The prominent features are as follow:

- Cost effective

- Longer life

- Light in weight

- Easy to handle at site

- Easy to interchange

We also manufacture ventury used in Filter Bag cages made out of Aluminium, SS, GI in different dia and lengths.

Cloth for Filter Press

wif filter Cloth for Filter Press are made of superior quality that pass strict sample test with the use of advanced technology such as CAD / CAM system.

Filter press requirements are met using wide range of cloths:

- Cloth for traditional filters

- Twin cloth with a connection neck for automatic filter process (Sizes up to 2150 mm)

- Cloths for membrane plates

- Cloths for sealed edges and reinforcements

- Under-cloths for drainage and other details matching machine needs (upon request)

wif filter synthetic fibres also offer customers excellent solutions for:

- Mechanical resistance and performance against chemical agents and

temperature - Filtering efficiency with adequate flow

- A non – adhesive surface effects.

Technologically component wif filter pvt. ltd. sales engineers are always available to help our customers select the appropriate fabric for their specific needs.

Air Filter

Leading manufacturer and exporter of Pre Filters presents a wide range of Pre Air Filters that fits to distinct industrial applications, you always need for. These Industrial Pre Filters are used by many reputed clients for various Industrial Air Conditioning & Ventilation applications in Offices, Cinema Halls, Kitchen Paint Booth in Automobile Industries, Chemicals & Pharmaceutical Industries, where low resistance & high dust holding capacity is essential. All Pre Filters designed and developed by our experts are durable and require negligible maintenance